Combo

You supply some parts we do the rest

Number of

Unique Parts

Fill in the exact quantity or 0 to wait for manually review.

Please enter the total number of single PCBs.(not the set number)

Number of

SMD Parts

Total quantity of SMD components for each board.

Number of

Through-Hole Parts

Total quantity of through holes components for each board.

Assembly Side(s)

Top side

Bottom side

Both sides

Are parts mounted on one side only, or both sides?

Conformal coating

Please contact your sales representative.

Select PCBgogo

PCB Order#

If you ordered pcb already on PCBgogo, you only need to select the pcb order number here so we can use the file from this pcb order to do stencil.

Detailed information

of assembly

Price does not include PCB fabrication or the cost of components, exact quotation will be updated after all the files you uploaded pass review or contact service@pcbgogo.com for help.

PCB Prototype

The above PCBs need assembly service

Thickness

0.203

0.305

0.508

0.813

1.524

Unit: mm

Thickness

0.254

0.338

0.508

0.762

1.524

Unit: mm

Different Design

in Panel

it means- we will charge extra panel costs when there are different

kinds in 1 PCB design. For same kinds, it needn't charge.

Size (single)

inch”↔mm

Inch”↔mm conversion

If you enter in units of inches and press the [Convert] button, it will be converted into units of millimeters in the quotation form.

Panel Way

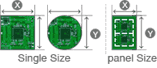

Single piece

Panel by Customer

Panel by PCBgogo

The above panel way and panel size are for reference only which shall be subject to the review of our PCB engineer.

Panelization Detail:

Panel size:

0.00 X

0.00 mm

0 panels =

0 pcs individual PCBs

Image for panelized board ↓ (for reference only)

The final price will vary depending

on the paneling method and quantity.

The full board are by only one single board or be arrayed with the same or different PCBs

Layers

1 Layer

2 Layers

4 Layers

6 Layers

8 Layers

10 Layers

12 Layers

14 Layers

FR4-TG

TG 130

TG 150

TG 170

S1000H TG 150

S1000-2M TG 170

Thickness

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

2.4

2.8

3.0

3.2

3.6

3.8

4.0

Unit: mm

Min Track/Spacing

3/3mil

4/4mil

5/5mil

6/6mil

8/8mil ↑

Min Hole Size

0.15mm

0.2mm

0.25mm

0.3mm ↑

0.8mm ↑

1.0mm ↑

No Drill

Solder Mask

Green

Red

Yellow

Blue

White

Purple

Black

Matte black

Matte green

None

Usually green color, the lead time will be longer if you choose other colors.

Gold Fingers

Yes

No

Bevelling

No

Yes (20°)

Yes (30°)

Yes (45°)

HASL with lead

HASL lead free

Immersion gold(ENIG)

OSP

Hard Gold

ENEPIG

Immersion silver(Ag)

None

*The above options are only Gold fingers Surface Finish

Thickness of

Immersion Gold

1U"=0.0254um

Au/Ni thickness

Au:10U"/Ni:120U"

Please choose other options of Gold /Nickel thickness here

1U"=0.0254um

Au:3U"/Ni:120U"

Au:5U"/Ni:120U"

Au:10U"/Ni:120U"

Au:15U"/Ni:120U"

Au:20U"/Ni:120U"

Au:25U"/Ni:120U"

Au:30U"/Ni:120U"

Please Enter | Au:

U"/Ni:

U"

Surface Finish

HASL with lead

HASL lead free

Immersion gold(ENIG)

OSP

Hard Gold

ENEPIG

Immersion silver(Ag)

None

Thickness of

ENEPIG

Ni:200U" / Pd:2U" / Au:2U"

Please choose other options of Au/ Pd thickness here

Ni:200U" / Pd:1U" / Au:1U"

Ni:200U" / Pd:2U" / Au:2U"

Ni:200U" / Pd:3U" / Au:3U"

Ni:200U" / Pd:4U" / Au:4U"

1U"=0.0254um

Thickness of

Immersion Gold

1U"=0.0254um

Au/Ni thickness

Au:3U"/Ni:120U"

Please choose other options of Gold /Nickel thickness here

1U"=0.0254um

Tick "Yes" to agree PCBGOGO to replace "HASL" to "ENIG" randomly because

of factory fabrication requirement.

Yes

No

Via Process

Tenting vias

Plugged vias

Vias not covered

Tips: If you use .PCB and .PCBDOC format file, we will fabricate the drills in PCBs as your selected options. This option is invalid if your file is Gerber file , as we will do according your Gerber file.

Finished Copper

1 oz. Cu

2 oz. Cu

3 oz. Cu

4 oz. Cu

5 oz. Cu

6 oz. Cu

7 oz. Cu

8 oz. Cu

9 oz. Cu

10 oz. Cu

Inner Copper

1 oz

1.5 oz

2 oz

3 oz

4 oz

5 oz

6 oz

+Additional Options

(Castellated holes ,Edge Plating ,impedance control, buried / blind vias,Custom Stackup,UL Marking)

Below options, their cost is not included in the online quotation

Peelable Soldermask

Coating material could be removed after board through wave soldering

Do not add PCB order number

Do not add PCB order number on board( extra +$1)

Half-cut/Castellated Holes

PTH holes or vias that are cutted through to create a partial or half hole to form an opening into the side of the hole barrel.Generally they are used for mounting a PCB to another one.

Edge Plating

The partial edge of the PCB plated with copper

Impedance control

The resistance to the flow of current, represented by an electrical network of combined resistance, capacitance and inductance reaction,usually in high-frequency circuits

Halogen-Free

Halogen-free PCB, it should have less than 900 parts per million of chlorine or bromine, with less than 1,500 ppm of total halogens.

Buried/blind vias

High-density multi-layer PCBs may have microvias: blind vias are exposed only on one side of the board, while buried vias connect internal layers without being exposed on either surface.

Custom Stackup

Apply to multilayer pcbs only.Stack-up refers to the arrangement of copper and insulating layers that make up a PCB before starting board layout design.

Carbon Mask

Carbon ink creates surface resistors and a protective contact surface for switches.

Via in pad

The microvias filled with non-conductive epoxy then capped and plated over

Via filled with resin

The microvias filled with epoxy

Countersinks/Counterbores

Countersink is a cone shaped hole in PCB for the tapered head of a screw. Counterbore is flat-bottomed hole and its sides are drilled straight down, usually used to fit a hex-headed cap or screw

Z-axis milling

A variable level elevation can be milled at the edge or within a circuit board. This is called Z-axis milling.

Confirm work file

work file is the Gerber file after PCBGOGO optimizes your PCB project, and we will have customers confirmed their work file, the lead time of your order will be counted by the time of work file confirmed

Other Special

Request

Your number will be added to the board. Kindly leave a note if you do not require this additional service.

CALCULATE

PCB Build time

For Rigid-Flex boards, the price will be showed and confirmed after review.

For Rogers boards, the price will be showed and confirmed after review.

Tell us more about your PCB&PCBA requirements or anything else you'd like us to know.

The price will be showed and confirmed after review.

Assembly Service Price

PCBA Lead time according to quotation list from our sales.

Shipping costs

UNITED STATES OF AMERICA

UNITED STATES OF AMERICA

UNITED STATES OF AMERICA

AFGHANISTAN

ALBANIA

ALGERIA

AMERICAN SAMOA

ANDORRA

ANGOLA

ANGUILLA

ANTIGUA

ARGENTINA

ARUBA

AUSTRALIA

AUSTRIA

AZERBAIJAN

BAHAMAS

BAHRAIN

BANGLADESH

BARBADOS

BELGIUM

BELIZE

BENIN

BERMUDA

BHUTAN

BOLIVIA

BONAIRE

BOSNIA AND HERZEGOVINA

BOTSWANA

BRAZIL

BRUNEI

BULGARIA

BURKINA FASO

BURUNDI

CAMBODIA

CAMEROON

CANADA

CANARY ISLANDS, THE

CAPE VERDE

CAYMAN ISLANDS

CENTRAL AFRICAN REPUBLIC

CHAD

CHILE

CHINA, PEOPLES REPUBLIC

COLOMBIA

COMMONWEALTH NO. MARIANA ISLANDS

COMOROS

CONGO

CONGO, THE DEMOCRATIC REPUBLIC OF

COOK ISLANDS

COSTA RICA

COTE D IVOIRE

CROATIA

CURACAO

CYPRUS

CZECH REPUBLIC, THE

DENMARK

DJIBOUTI

DOMINICA

DOMINICAN REPUBLIC

EAST TIMOR

ECUADOR

EGYPT

EL SALVADOR

ERITREA

ESTONIA

ETHIOPIA

FALKLAND ISLANDS

FAROE ISLANDS

FIJI

FINLAND

FRANCE

FRENCH GUYANA

GABON

GAMBIA

GEORGIA

GERMANY

GHANA

GIBRALTAR

GREECE

GREENLAND

GRENADA

GUADELOUPE

GUAM

GUATEMALA

GUERNSEY

GUINEA REPUBLIC

GUINEA-BISSAU

GUINEA-EQUATORIAL

GUYANA (BRITISH)

HAITI

HONDURAS

HONG KONG

HUNGARY

ICELAND

INDIA

INDONESIA

IRAQ

IRELAND, REPUBLIC OF

ISRAEL

ITALY

JAMAICA

JAPAN

JERSEY

JORDAN

KENYA

KIRIBATI

KOREA, REPUBLIC OF (SOUTH K.)

KOSOVO

KUWAIT

LAO PEOPLES DEMOCRATIC REPUBLIC

LATVIA

LEBANON

LESOTHO

LIBERIA

LIBYA

LIECHTENSTEIN

LITHUANIA

LUXEMBOURG

MACAU

MACEDONIA, REPUBLIC OF

MADAGASCAR

MALAWI

MALAYSIA

MALDIVES

MALI

MALTA

MARSHALL ISLANDS

MARTINIQUE

MAURITANIA

MAURITIUS

MAYOTTE

MEXICO

MICRONESIA, FEDERATED STATES OF

MOLDOVA, REPUBLIC OF

MONACO

MONGOLIA

MONTENEGRO, REPUBLIC OF

MONTSERRAT

MOROCCO

MOZAMBIQUE

MYANMAR

NAMIBIA

NAURU, REPUBLIC OF

NEPAL

NETHERLANDS, THE

NEVIS

NEW CALEDONIA

NEW ZEALAND

NICARAGUA

NIGER

NIGERIA

NIUE

NORWAY

OMAN

PAKISTAN

PALAU

PALESTINE

PANAMA

PAPUA NEW GUINEA

PARAGUAY

PERU

PHILIPPINES, THE

POLAND

PORTUGAL

PUERTO RICO

QATAR

REUNION, ISLAND OF

ROMANIA

RWANDA

SAINT HELENA

SAMOA

SAN MARINO

SAO TOME AND PRINCIPE

SAUDI ARABIA

SENEGAL

SERBIA, REPUBLIC OF

SEYCHELLES

SIERRA LEONE

SINGAPORE

SLOVAKIA

SLOVENIA

SOLOMON ISLANDS

SOMALIA

SOMALILAND, REP OF (NORTH SOMALIA)

SOUTH AFRICA

SOUTH SUDAN

SPAIN

SRI LANKA

ST. BARTHELEMY

ST. EUSTATIUS

ST. KITTS

ST. LUCIA

ST. MAARTEN

ST. VINCENT

SURINAME

SWAZILAND

SWEDEN

SWITZERLAND

TAHITI

TAIWAN

TAJIKISTAN

TANZANIA

THAILAND

TOGO

TONGA

TRINIDAD AND TOBAGO

TUNISIA

TURKEY

TURKMENISTAN

TURKS AND CAICOS ISLANDS

TUVALU

UGANDA

UKRAINE

UNITED ARAB EMIRATES

UNITED KINGDOM

URUGUAY

UZBEKISTAN

VANUATU

VATICAN CITY

VIETNAM

VIRGIN ISLANDS (BRITISH)

VIRGIN ISLANDS (US)

YEMEN, REPUBLIC OF

ZAMBIA

ZIMBABWE

DHL

DHL

FedEx-IP

FedEx-FICP

EMS

HK post

China Post

E-packet

SF Express

OCS

Other shipping way

! temporarily out of service

3-7 Days | wt: 0.53 kg

CHN Time Zone(GMT+8):

2024/05/02 12:32:24

Payment before 2024/05/02 17:00

(GMT+8 Only PCB)

-

PCB Cost

$

-

Stencil Cost

$

-

Assembly Cost

$

-

Shipping

$

Total

Amount

Early Bird Discount -$7

Currency

-

$1 PCB Prototypes for New Users

- PCB Cost: $1

- Shipping: $0

Total discount amount: $1

Note: The final discounted total price is subject to review!

Register now!

This order is eligible for PCBGOGO’s preferential policy. Please contact the

sales representative or

service@pcbgogo.com.

Your target price($)

ADD TO BASKET

CALCULATE

The price is rough quote. If you need the accurate price with components cost, please register and upload the files.

The EUR and GBP prices are for reference only.

The final payment price is up to the PCBGOGO transaction exchange rate.