Circuit board assembly is a crucial process in the manufacturing of electronic devices, serving as the backbone for the functionality and performance of countless technologies. From smartphones to industrial machinery, circuit boards are the unsung heroes that enable the seamless integration of electronic components. PCBgogo is a company that provides printed circuit board (PCB) assembly and fabrication services. They offer online PCB ordering and circuit board assembly services for individuals and businesses looking to prototype or manufacture electronic devices.

PCBgogo allows users to upload their PCB designs, specify their requirements, and place orders for the fabrication and assembly of printed circuit boards. The company typically offers services such as PCB manufacturing, turnkey PCB circuit board assembly, and component sourcing.

PCBgogo circuit board assembly line

Understanding Circuit Board Assembly:

Circuit board assembly relies on a set of fundamental components that collectively form the backbone of electronic devices. These components work in harmony to create a functional and interconnected system.

1. Basic Components:

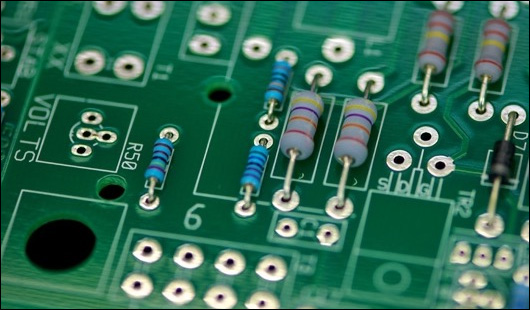

Printed Circuit Board (PCB): The foundation of any electronic device, the PCB provides a platform for mounting and connecting various electronic components. At the core of circuit board assembly lies the PCB, a flat board made of non-conductive material with a conductive pathway etched or printed onto its surface.

The PCB serves as structural foundation for mounting and connecting various electronic components. It acts as a roadmap, guiding the flow of electrical signals between components, ensuring precision and order.

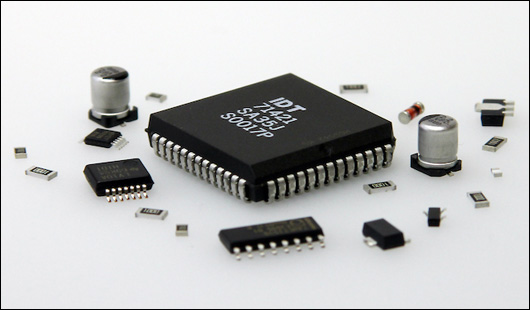

Electronic Components: Resistors, capacitors, transistors, and integrated circuits are among the components soldered onto the PCB, forming the functional elements of the circuit. The electronic components constitute the active and passive elements that bring the circuit to life. These include resistors, capacitors, transistors, and integrated circuits (ICs).

1. Resistors:

Impede the flow of electrical current and controlling its amount that passes through a circuit.

2. Capacitors:

Store and release electrical energy, providing stability and filtering in the circuit.

3. Transistors:

Act as electronic switches, amplifying or controlling the flow of current.

4. Integrated Circuits (ICs):

Miniaturized circuits containing numerous interconnected components, enhancing functionality and reducing space requirements.

5. Connectors and Interfaces:

Connectors and interfaces play a crucial role in facilitating communication. These include USB ports, HDMI connectors, and other interfaces specific to the intended application.

6. Power Supply Components:

Ensuring a stable and regulated power source is essential for proper functioning of electronic devices. Power supply components such as voltage regulators, transformers, and diodes regulate and control the flow of electricity, safeguarding sensitive components from voltage fluctuations.

7. Inductors and Transformers:

Inductors store energy in a magnetic field and resist changes in current, while transformers transfer electrical energy between circuits. Both components are vital in managing power distribution and minimizing electromagnetic interference.

8. Diodes:

Diodes allow current to flow in one direction only, preventing reverse flow and protecting sensitive components from damage. They play a crucial role in rectification and signal modulation.

9. Microcontrollers and Microprocessors:

Acting as the brain of the circuit, microcontrollers and microprocessors interpret and execute instructions. They are responsible for data processing, decision-making, and overall system control.

10. Sensors:

Sensors detect changes in the environment and convert them into electrical signals. These components are integral in devices that require interaction with the external world, such as temperature, motion, and light sensors.

Types of Circuit Board Assembly:

· Through-Hole Assembly (THA): This traditional method involves inserting component leads through holes in the PCB and soldering them on the opposite side. Through-Hole Assembly (THA) is a conventional method in circuit board assembly where electronic components inserted into pre-drilled holes on the printed circuit board (PCB).

The leads of the components protrude through the bottom of the PCB, and soldering is applied on the opposite side, forming secure connections. THA is known for its durability and reliability, making it suitable for applications where robustness is crucial.

Through-hole Assembly-PCBgogo

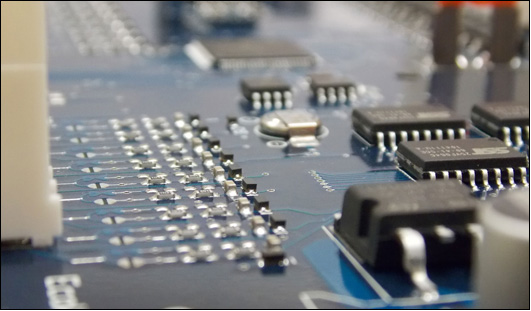

· Surface Mount Technology (SMT): Surface Mount Technology (SMT) is a modern approach to circuit board assembly where electronic components directly mounted onto the surface of the printed circuit board (PCB). This method eliminates the need for component leads and drilled holes, allowing for a more compact design. SMT is characterized by its high precision and efficiency, often utilizing automated pick-and-place machines for component placement.

SMT is particularly advantageous for small, lightweight electronic devices such as smartphones and tablets, where size and weight considerations are critical.

Surface Mount Technology-PCBgogo

Circuit Board Assembly Procedures:

1. Design and Prototyping:

· The process begins with the design of the PCB layout using specialized software.

· Prototyping helps identify and address any design flaws before mass production.

2. PCB Fabrication:

· Once the design is finalized, PCB is fabricated, involving etching copper layers, drilling holes, and applying protective layers.

· High precision is crucial to ensure the correct placement of components during assembly.

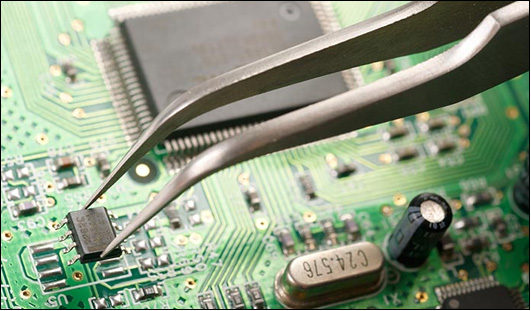

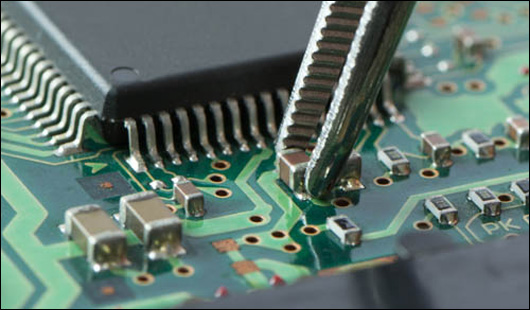

3. Component Placement:

· For THA, components are manually inserted into pre-drilled holes, while SMT employs automated pick-and-place machines.

· Component placement accuracy is paramount to avoid electrical issues and ensure optimal functionality.

4. Soldering:

· The soldering phase establishes the electrical connections between components and the PCB.

· Various soldering techniques including wave and reflow soldering are employed based on the circuit board assembly type.

Reflow soldering/Oven equipment

Wave soldering equipment

5. Quality Control and Testing:

· Rigorous quality control checks are conducted to identify defects, such as solder bridges or faulty components.

· Functional testing is conducted to verify that the assembled circuit aligns with specified performance standards.

· There are a few testing methods and machinery that are crucial for PCB testing standards such as:

AOI Inspection

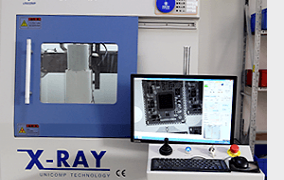

X-ray Equipment

QC Inspection

After-sale testing

QC Inspection AOI Inspection

X-Ray inspection machine-PCBgogo PCB Cleaning machine-PCBgogo

Key Considerations in Circuit Board Assembly:

1. Material Selection:

The choice of materials, including PCB substrate and soldering materials, affects the board's durability and performance.

2. Environmental Considerations:

Compliance with environmental regulations, such as RoHS (Restriction of Hazardous Substances), is essential for responsible manufacturing.

3. Automated vs. Manual Assembly:

Automated assembly is faster and more precise but may be costlier, making the choice dependent on production volume and budget constraints.

4. Prototyping and Iterative Design:

Prototyping allows for iterative design improvements, minimizing the risk of mass-producing flawed circuit boards.

Conclusion:

Mastering circuit board assembly is crucial for the production of reliable electronic devices. PCBgogo contributes to circuit board assembly by offering online PCB fabrication and assembly services, streamlining the process with user-friendly platforms and efficient production capabilities. Whether opting for traditional through-hole assembly or the modern surface mount technology, understanding the intricacies of the assembly process and adhering to best practices is essential. By considering key factors such as material selection, environmental regulations, and assembly methods, manufacturers can ensure the production of high-quality circuit boards that form the backbone of our interconnected world.