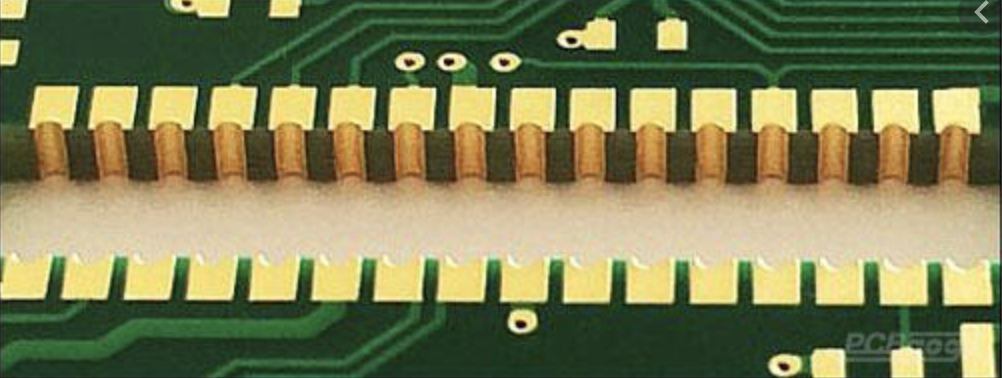

Plated half-hole or castellated-hole, is a stamp-shaped edge through cutting in half on the outline. Plated half-hole is a higher level of plated edges for printed circuit boards, which is usually used for board-to-board connections. This technology helps to minimize the entire size of the final product.

Most of the plated half-hole PCBs are small modules with high-density delicate pitch components. Compared to SMT and THT, board-to-board soldering is used to mount a single module board to another board. Then, plated half-holes become more prevalent in PCB manufacturing.

The applications and advantages of plated half-holes

Plated half-hole is an economic connection technology, which makes the PCB as a surface mount sub-assembly. For example, the Wi-Fi module or Bluetooth module can be used as an independent part to connect to another board during the PCB assembly process. Usually, plated half-hole is used to combine two PCBs with different technologies together. E.g., the complex microcontroller module is combined with a universal design PCB. But we need to know that if one board need to stack on top of another board by using plated half-holes, there are two requirements: the space between the two boards should be zero, and electrical contacts are needed, not just physical connection.

Plated half-hole provides flexibility in PCB design and smaller sizes without compromising quality. Besides, plated half-hole will improve the process reliability of PCBs through accurately milled. And it can protect the electroplating layer from mechanical damage. Therefore, the PCB with plated half-holes is widely used in industries such as high-end consumer electronics, computers, telecommunications, power, automobile, and industrial controls, etc.

____________________________________________________________________________________________________________________________

Some rules in plated half-hole design from PCBGOGO

● The minimum diameter of the plated half-hole is 0.6mm.

● The minimum distance between two half holes is 0.55mm.

● The minimum space between pad and pad is 0.25mm.

● Use larger hole diameter and larger outer layer pad if possible.

● ENIG is recommended for surface finish.

● As far as possible, the inner layer pad is connected to the plating hole to improve stability and avoid burring.

____________________________________________________________________________________________________________________________

Plated half-hole is not a simple drilling process, which needs excellent processes and professional technologies. Therefore, plated half-holes usually need extra charges. Please contact the manufacturer if you are not sure about the plated details or the fabrication cost. And if you have more stringent requirements for plated half-hole, please contact us through online service or Emails. PCBGOGO will provide the best solutions for you!