In the intricate realm of electronics manufacturing, the PCB Assembly stands as a critical juncture, where precision and efficiency converge to bring designs to life. This article provides an in-depth exploration of PCB assembly, covering various methods, processes, types, testing machinery, and the unique capabilities of PCBGOGO, a distinguished player in the industry. PCBGOGO stands as a genuine PCB assembly manufacturer situated in Shenzhen, boasting three manufacturing facilities outfitted with cutting-edge production equipment.

Assembly Methods and Processes:

PCB assembly can be approached through two fundamental methods:

1. Manual Assembly:

Suited for low-volume projects.

Involves the hand-placement of components on the PCB.

Rigorous visual inspection to ensure accuracy.

2. Automated Assembly:

Preferred for larger projects.

Utilizes advanced machinery for precise component placement.

Offers speed and accuracy in the assembly process.

Types of PCB Assembly:

PCB assembly standards vary based on the application and desired reliability.

· Class 1 Standard:

Basic electronic products with minimal performance requirements.

Commonly used in consumer electronics.

· Class 2 Standard:

Standard for most electronic products.

Applicable where continued performance and extended life are required.

· Class 3 Standard:

High-reliability products, such as aerospace or medical devices.

Demands maximum attention to detail and reliability.

Quick turn prototype PCB assembly:

Quick turn prototype PCB assembly is a specialized service offered by PCBGOGO, showcasing their expertise in efficiently bringing designs from conception to reality. As a prominent player in the electronics manufacturing industry, PCBGOGO excels in providing rapid turnaround times for prototype PCB assembly, catering to the dynamic needs of innovators and engineers.

Turnkey PCB Assembly:

Turnkey PCB assembly services provide a comprehensive and hassle-free solution for clients seeking a one-stop-shop for their printed circuit board (PCB) assembly needs. In the realm of electronics manufacturing, turnkey services offered by companies like PCBGOGO streamline the entire process, from design and procurement to assembly and testing.

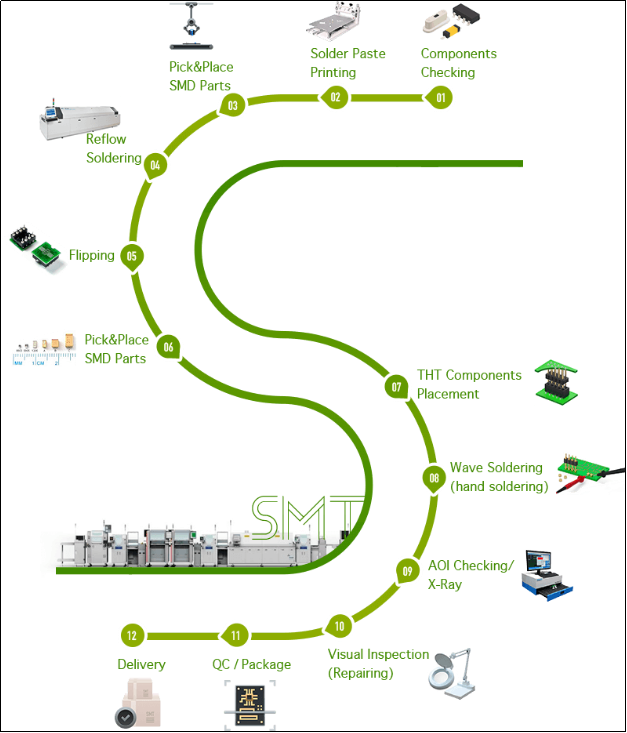

PCB Assembly Processes:

Step 1: Order Placement and Design Review:

Clients submit PCB designs and assembly requirements. PCBGOGO reviews designs for manufacture ability and offers feedback.

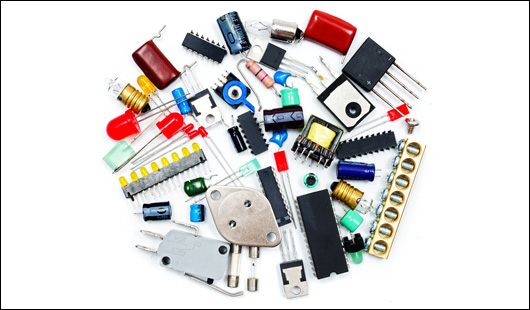

Step 2: Material Procurement

Once the design is approved, the next step involves procuring the necessary materials, component sourcing. PCBGOGO, with its extensive network and partnerships, sources high-quality components and PCBs. The commitment to quality begins at this stage, as using reliable components is crucial for the overall performance and longevity of the final product.

Step 3: Stencil Fabrication

A key element in the PCB assembly process is the fabrication of stencils. These stencils are precision tools used for applying solder paste to the PCB. PCBGOGO employs advanced stencil fabrication techniques, ensuring accuracy in solder paste deposition, a critical factor for flawless soldering in subsequent steps.

Step 4: Pick & Place

With materials in hand and stencils ready, the assembly process kicks into high gear. PCBGOGO's automated machinery takes center stage, as the pick & place system accurately positions components on the PCB with lightning speed. Leveraging CAD data, the machinery ensures precise placement, a task that would be time-consuming and prone to error if done manually.

YAMAHA Pick and Place machine

JUKI Pick and Place machine

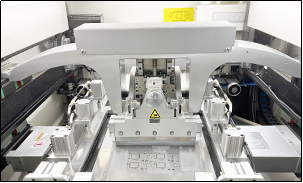

Step 5: Solder Paste Application

Solder paste, a mixture of tiny solder spheres and flux, is applied to the PCB using the stencils. This step is pivotal, as it sets the stage for the components to be securely attached during the soldering process. PCBGOGO's commitment to quality is evident here, with automated systems guaranteeing consistent and uniform solder paste application.

Solder paste printing machine

Step 6: Reflow Soldering

The heart of the assembly process lies in reflow soldering, where the PCB with components and solder paste undergoes a carefully controlled heating process. PCBGOGO adheres to Class 1 standard for all soldering during this phase, ensuring a baseline of quality that surpasses the requirements for many consumer electronics.

Step 7: Automated Optical Inspection (AOI)

With components securely soldered, the assembly undergoes thorough scrutiny. PCBGOGO employs Automated Optical Inspection (AOI) technology to verify component positions, orientation, and solder quality. This automated approach enhances the speed and accuracy of the inspection process, minimizing the risk of human error.

AOI inspection

Step 8: Manual Inspection for Small Projects

While larger projects benefit from the efficiency of automated processes, PCBGOGO recognizes the importance of a hands-on approach for very small volume PCBA projects. These projects undergo meticulous manual inspection to ensure precision and quality that meets the standards set by PCBGOGO.

Step 9: Quality Assurance and Testing

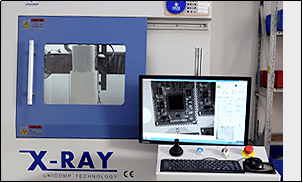

Before the assembled PCBs are deemed ready for delivery, PCBGOGO subjects them to rigorous quality assurance and testing. This involves functional testing, X-RAY, and AOI testing machine.

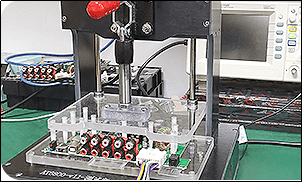

Functional testing of PCB

PCB cleaning machine

X-Ray PCB testing machine

Complementing these advanced technologies are highly skilled technical personnel, making PCBGOGO a hub for top-tier PCB assembly services.

Step 10: Packaging and Delivery

The final step involves carefully packaging the assembled PCBs and delivering them to the client. PCBGOGO recognizes the importance of a smooth and secure delivery process, ensuring that the client receives the finished product in pristine condition.

Key features of PCBGOGO's PCB assembly include:

· Swift Turnaround

· Flexible Order Sizes

· High-Quality Components

· Precision in Assembly

· Seamless Integration with Design Iterations

· Expert Support

· Cost-Effective Solutions

Conclusion:

PCB assembly emerges as a crucial choreography, where precision meets efficiency. PCBGOGO, with its commitment to quality and utilization of advanced technologies, stands as a beacon in the industry. By seamlessly blending automated machinery with manual inspection and offering flexibility in soldering standards, PCBGOGO ensures that each PCB assembly bearing its mark is a testament to precision, reliability, and innovation. As technology continues its relentless march forward, PCBGOGO remains at the forefront, defining the standards for the next generation of electronic marvels.