What Is Solder Flux And How Do You Use It?

Nowadays, there are soldering wires with a tubular structure in the market, filled with flux on the inside of hollow area. However, it can remove the flux in the external under the case of small soldering jobs. As you know, soldering is essential for the complex motherboard of a computer or a simple electronics hobby project while creating most electronics or electrical circuits. Only have the correct technique and right tools can it get the perfect bond.

However, so many beginners and non-professionals tend to heat up the gun and begin soldering immediately, it may have an effect most of time, but it is totally unprofessional and rarely reliable. So you should use the solder flux so that there is a perfect and reliable solder. Therefore, it’s important for you to find out what solder flux is, how it works, as well as what problems do you have while soldering without using solder flux.

What is solder flux?

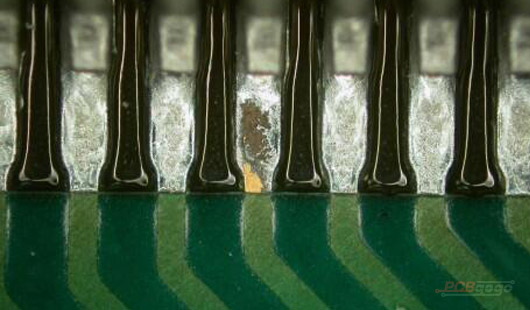

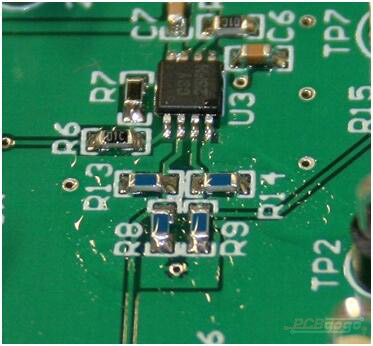

Solder flux is a very useful material that contributes to achieving a perfect soldering bond, which is activated by the heat of the soldering operation to remove the last layer of oxidized metal so that the solder will wet the base metal and create a good joint, it’s used in automatic PCB assembly and hand soldering, and is mainly in cleaning the surface of PCB before soldering process.

Types of solder flux

There are three major types of solder flux based on electronics industry standard.

Rosin flux: one of the oldest types of flux, which is mainly made up of natural resin extracted from the oleoresin of pine trees and refined, however, the modern rosin is blended with different fluxes to optimize its performance.

Flux is easy to flow particularly in a hot weather, make it quick to remove the oxides, and is good for removing foreign particles from the surface of the metal being soldered. Though rosin flux is acid as liquid, it will be inert and solid when it cools. Because rosin flux is inert as solid, it can be left on the circuit board without harming the circuit unless the circuit will warm to the point where the rosin may be liquid and eat away at the connection. So it’s great to remove rosin flux reside from a board. What’s more, flux residue should be removed with alcohol if make it important to use a conformal coating or PCB cosmetics.

Organic acid flux: it’s also known as water soluble flux, which is made up of organic materials other than rosin or resin. There are some common weak acids used in organic acid flux, such as citric, lactic, as well as stearic acids. They are combined with solvents like isopropyl alcohol and water. Organic acid flux is more quick and stronger than rosin flux as cleaning the oxides off, in addition, it also has a good soldering with great flux activity, making it easy to clean the circuit board with regular water. However, it needs to remove the flux residue as soldering because the OA residue will make an effect on the operation and performance of a PCB with conductivity.

Inorganic acid flux: another solder flux type that works better with stronger metals for instance brass, copper and stainless steel. You will need to clean the surface completely so that remove any corrosive residues from the surfaces if you use the inorganic acid flux. However, it will achieve a perfect solder joint if the residues are on the surface.

Why is solder flux used in soldering?

Clean and remove any oxide and impurities from a PCB, which is the the main function or use of flux in any printed circuit board assembly or rework. It may have a poor solder joint for the oxides deposited on the board, and there will be poor electrical conduction or poor flow of electricity through the circuit.

Soldering flux makes a good effect on soldering and wetting, as well as is good for de-oxidizing metals (copper tracks on the board and leads of electronic components). the activators in the flux promote wetting of the molten solder to the surface mount lands and component terminations or leads by removing oxides and other surface contaminants.

How to use solder flux?

Solder flux is available as paste in small jars/tin cans, also as liquid in jars/bottles or flux pens. for soft soldering, organic flux is typically used, but inorganic acid based flux may be used in non-electrical applications. So in general, the flux used for soldering, brazing is inorganic in nature, however, it may contain organic compounds as well, which are activated at higher temperatures.

The following is how to use solder flux:

1. You should clean the metal contact with a good solvent before using the soldering flux so that remove the dust, grime as well as excessive oxidation that may be present.

2. Then, it needs to apply an even coat of the flux to the surfaces where the actual soldering is slated to happen. But a tip you need to know, it can’t heat at this stage.

3. It should be placed on the metal contacts covered with flux when the tip of the soldering gun is hot and ready. And it should melt the flux and spread, covering the metal surface, which will remove the oxide layer, until the flux is present.

4. It should introduce and melt the soldering wire after vaporizing the flux, making sure the solder bonds before oxidizing again so that there are an effective soldering.

Conclusion

There is no doubt that solder flux is a very useful material that cleans surface of PCB before soldering process and removes oxides which form on electrical contacts, as well as make a good effect soldering the metals so that there will be a great bonding.

If you have any questions, or need more information on solder mask or solder paste, please feel free to contact us with service@pcbgogo.com, we will be happy to help you.