When should I choose 2 layer PCB or 4 layer PCB?

When it comes to PCBs, there are some types of PCB you maybe use in your electronic project, such as 1 layer PCB, 2 layers PCB, 4 layers PCB as well as 6 layers PCB and so on. However 1 layer PCB, 2 layers PCB and 4 layers PCB are the most common used in PCB fabrication. So you need to know whether you will use a 1 layer PCB, 2 layers PCB or multilayer PCB before designing the printed circuit board. What’s more, you also need to know which types of PCB is better for you depends on the project you are using as it determines the complexity of a board’s structure in electronic PCB industry.

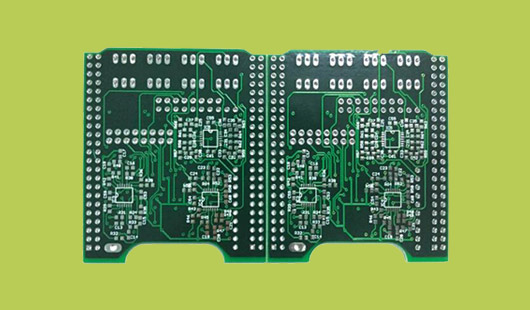

In general, multilayer PCB is used in more complicated devices, but 1 or 2 layer PCB is used for simple ones. Needless to say, it is more popular for electronic engineer to choose multilayer PCB because it can provide high signal intensity. And 2 layers PCB is the most common among all the PCB types as it can accommodate interconnects on both sides. So we will explain what is the difference between 2 layers PCB and 4 layers PCB, as well as how to choose the correct type for your project.

2 layers PCB vs. 4 layers PCB: what is the difference?

You can surmise what the apparent difference is between the 2 layers PCB and 4 layers PCB according to their names. 2 layers PCB has two sided traces with a top and bottom layer, while 4 layers PCB has 4 layers. If you have a better understanding of two types of PCB boards, you will find that there are many differences in how they are constructed and how to work.

2 layers PCB

2 layers PCB has more layers than a 1 layer PCB but fewer than a multilayer PCB. 2 layers PCB can mount conductive copper and components on both sides of the printed circuit board so that the traces can cross over each other. So it leads to a higher density of boards without the need of point-to-point soldering. So it’s difficult to fabricate the 2 layers PCB because they are more complex than 1 layer PCB. However, it’s better to use the 2 layers PCB compared to 1 layer PCB.

4 layers PCB

4 layers PCB can support a high level of PCB complexity because they are made up of four copper layers laminated together. What’s more, the PCB manufacturers begin to use a core that has the same material as a typical 2 layers PCB. And after etching the inner core, they add a layer of prepreg, a soft fiberglass, which remains the layers together and is the hard fiberglass after the board goes through a hot press. So 4 layers PCBs are durable and tough after the curing process. Needless to say, it will use one core, prepreg and copper foil for the top and bottom layers if the manufacturer is fabricating a 4 layers PCB.

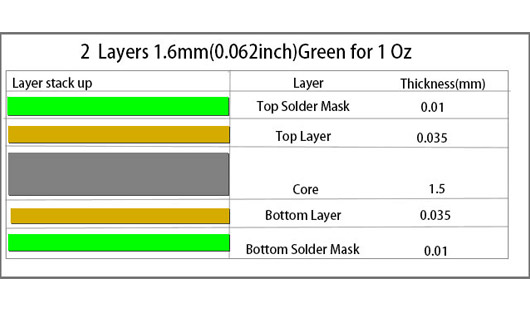

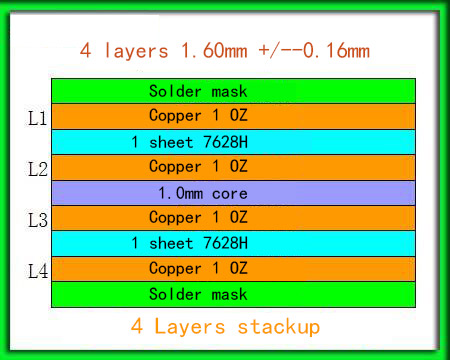

The stackups of 2 layers PCB and 4 layers PCB

It is obvious that it describes layer 1 or the top layer as a signal layer on the 2 layers PCB stackup. The 0.0014-in.-thick layer is made of copper material; the copper amounts to about 1 oz, which have a good effect on the boards with 0.062 in., ±10% of final thickness. If your board is fabricated, these values maybe differ based on the necessary parameters.

On the other hand, it is quite complex for 4 layers PCB stackup because it not only contains two inner layers, inner layer 1 and 2, but also the top layer and bottom layer. For the top layer of 4 layers PCB stackup, the signal layer (0.0014 in. width) is followed by a prepreg layer with a thickness of 0.0091 in. and dielectric constant of 4.2. The top layer is copper material. The prepreg layer is followed by inner layer 1 (0.0014 in.), referred to as the plane. A core sublayer is part of inner layer 1, which has a width of 0.037 in. This is followed by inner layer 2, which is another plane layer made with 1 oz. copper and is 0.0014 in. thick. Another prepreg sublayer consists of two sheets that are 0.0091 in. thick forms part of inner layer 2. The last layer, the bottom layer, is also 0.0014 in. thick, and is a signal layer as well. It solders and places the interconnects on the top and bottom layers.

Designs of 2 layers PCB and 4 layers PCB

On one hand, the design of 2 layers PCB can offer more surface area for including a conductor pattern. Needless to say, the surface is two times larger than a 1 layer PCB. And vias in 2 layers PCB are used to create electrical connections that can achieve the routing of the traces to get to the opposite side of the board.

On the other hand, more surface area is available for traces in a 4 layers PCB design than that in a 2 layers PCB. The 4 layers PCB design refers to a prepreg layer that bonds two layers and a 1 layer PCB with applying heat and pressure. As well as prepreg can provide dielectric between the layers.

Functionality of 2 layers PCB and 4 layers PCB

there is no doubt that it has more functions in 2 layers PCB as there are not propagation delays or other problems if using the microstrip traces containing a ground plane. However, it’s more popular to use the 4 layers PCB design that is made up of ground and VCC plane layers and 2 signal layers. But the design is making great efforts with impedance and propagation delays.

Cost of 2 layer PCB and 4 layer PCB

There is no doubt that 4 layers PCB is more expensive than 2 layers PCB because of complexity of design and higher sensitivity. What’s more, there is a factor 4 layers PCB cost what the higher quality of signals, achieving by decreasing distortion and propagation levels. So more and more electronic engineers prefer to 4 layers PCBs due to the higher levels of signal integrity and reduced interference levels.

When should I choose 2 layers PCB or 4 layers PCB?

To decide when you choose 2 layers PCB or 4 layers PCB, you need to take the demands of your project into consideration and which type best meets them. There are some questions you need to know:

1. What is the maximum dimension of PCB can be? There are more functionality into a smaller space for 4 layers PCB.

2. What level of functionality do you need? If it is more complex for your project, you will need 4 layers PCB.

3. How about the durability? If you need to have a good durability, choosing 4 layers PCB.

4. What is the budget? If you take a suitable budget into consideration, it’s better to choose 2 layers PCB.

5. How quickly do you need your boards? 2 layers PCB has a fast lead time compared to 4 layers PCB.

In a word, you will also need to deal with more technical questions about requirements, for example the operation frequency, density as well as signal layers you need. We hope to help you with these questions if you need a PCB with 2 layers or 4 layers.