What Is The Difference Between FR-4 Material And Rogers Material?

As you know, printed circuit board plays an important role in electronic products, so you need to consider how to choose the right material in your PCB manufacturing. Needless to say, PCBGOGO can offer you the lowest possible costs as well as the very finest in high quality PCB fabrication and high quality PCB assembly. However, there are many different types of PCB materials, such as FR-4 material, HDI material, as well as Rogers PCB material and so on. In general, we use the standard FR-4 material for the printed circuit boards to help customers reduce product costs, which is a fine option, because FR-4 material is affordable and effective for many applications. However, FR-4 material us not the only type of PCB material, comparing to PCB material, FR-4 material and Rogers material is the important, but a lot of customers feel confused about them. So PCBGOGO will make an introduction of FR-4 material and Rogers material.

What is FR-4 material?

In fact, FR-4 refers to a grade of material rather than a material, which is a composite material for glass-reinforced epoxy laminate material. FR-4 is made up of woven fiberglass cloth with an epoxy resin binder that is flame resistant. And FR stands for flame retardant, it denotes that the material complies with the standard UL94V-0.

FR-4 Material

For electronic engineers and designers, FR-4 glass epoxy is a popular and versatile high-pressure thermoset plastic laminate grade with good strength to weight ratios. With near zero water absorption, FR-4 is most commonly used as an electrical insulator possessing considerable mechanical strength. The material is known to retain its high mechanical values and electrical insulating qualities in both dry and humid conditions. These attributes, along with good fabrication characteristics, lend utility to this grade for a wide variety of electrical and mechanical applications. So FR-4 can perform well in most environmental conditions.

What is Rogers PCB?

Rogers is a company that manufactures the laminate materials that are used to make circuit boards. Most circuit boards are made of a material known as FR4 (Flame Retardant level 4), which is a glass fiber / epoxy composite, with copper foil laminated on one or both sides.

Rogers will sell you FR-4 laminates (FR-4 core with copper laminate), they are better known for cores with better high frequency properties, such as PTFE (Teflon). They’re more expensive than fiber glass, but are less lossy at high frequencies. This makes them be good for RF circuit boards.

The difference between FR-4 material and Rogers material

1. FR-4 material is cheaper than Rogers material.

2. Comparing to FR-4 material, Rogers material is great with high frequencies.

3. FR-4 material has a high Df or dissipation factor than Rogers material, suffering more signal loss.

4. In impedance stability, Rogers material has a wider range of Dk values than FR-4 material.

5. For dielectric constant, FR-4 features a Dk of about 4.5, which is lower than Rogers material with around 6.15 to 11.

6. In temperature management, Rogers material has a less variation comparing to FR-4 material.

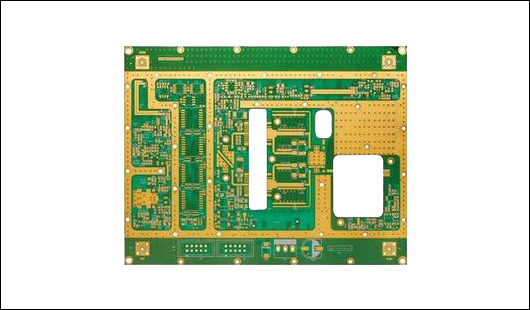

Roger Material

Why Rogers PCB material?

FR-4 material provides the fundamental standard for PCB substrates, keeping a widely effective balance between cost, durability, performance, manufacturability, as well as electrical properties. However, as performance and electrical properties plays an important role in your designs, Rogers materials have the advantages as follows:

Low electrical signal loss

Effective-cost PCB fabrication

Lower dielectric loss

Better thermal management

Wide range of Dk (dielectric constant) values (2.55-10.2)

Low outgassing for space applications

Improve impedance control

Glossary:

Dielectric materials

The dielectric materials is a substance with a poor conductor of electricity, and used as an insulating layer in the PCB build up, glass, mica, Porcelain, plastics and some metal oxides are good dielectrics. The dielectric material will more and more effective with the reduction of dielectric loss (the proportion of energy lost as heat). however, the material will unexpectedly start to conduct current if the voltage across a dielectric material is too great or the electrostatic filed is too intense, which is called dielectric breakdown. Comparing to FR-4, rogers material is less likely to demonstrate a dielectric breakdown.

Pre-preg

Pre-preg can make a good effect on the performance characteristics of the printed circuit board in PCB fabrication. What’s more, it is used for bonding the layers of a multilayer PCB together.

PCB fabrication with Rogers material or FR-4 material in PCBGOGO

undefined

With over 10 years as an industry leader, PCBGOGO is one of the most experienced PCB and PCB assembly manufacturer in China. highly specialized not only in quick-turn PCB prototype and PCB assembly, but also medium and small volume PCB fabrication. Neither fabricate PCB with Rogers material nor FR-4 material, PCBGOGO will try our best to fabricate your PCBs with the highest quality to meet your demands and committed to adhering to the strictest standards in PCB fabrication and assembly.

Get PCB Prototype Quote with FR-4 material and Rogers material Now.