What is ceramic PCB?

1. What is ceramic PCB?

2. The types of ceramic PCBs

3. The advantages of ceramic PCB

4. Why use ceramic PCB over other boards?

5. How to manufacture ceramic PCB?

6. The application of ceramic PCB

With the development of chip components and surface mount technology (SMT) in electronics industry, traditional printed circuit boards with organic laminates as based material are developing towards high density, high precision, and high reliability. Needless to say, ceramic PCB, as a relatively new type of printed circuit board, which has been widely used in electronics industry for years, and it is a more viable option for PCB designers, considered as an effective solution for miniaturization accomplishment of modern electronics products and electronic assembly technology. You will find that ceramic PCB has an advantage over traditional printed circuit board, what’s more, ceramic PCB is more versatile, less complex and offer superior performance because of its high thermal conductivity and minimal expansion coefficient (CTE).

What is ceramic PCB?

Ceramic PCB is a kind of heat conducting ceramic powder and organic binder, and the heat conduction organic ceramic PCB is prepared at a thermal conductivity of 9-20W/m. In other words, ceramic PCB is a printed circuit board with ceramic base material, which is highly thermally conductive materials such as alumina, aluminum nitride, as well as beryllium oxide, which can make a quick effect on transferring heat away from hot spots and dissipating it over the whole surface. What’s more, ceramic PCB is fabricated with LAM technology, which is a laser rapid activation metallization technology. So ceramic PCB is highly versatile that can take place of the entire traditional printed circuit board with a less complicated construction with enhanced performance.

![]()

Types of ceramic PCBs

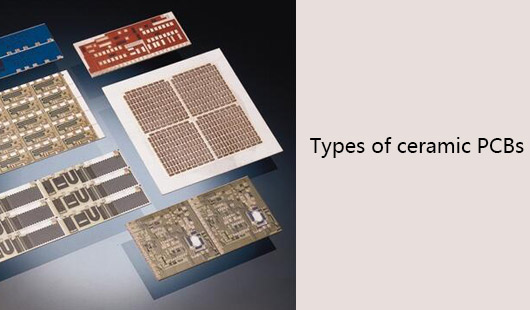

There are three main types of ceramic PCB in the electronic market based on the manufacturing method.

? High temperature ceramic PCB

? Low temperature ceramic PCB

? Thick film ceramic PCB

High temperature

As you know, high temperature may be the most popular types pf ceramic. In general, The ceramic PCB designed for high temperatures is often regarded as high temperature co-fired ceramic (HTCC) circuit, which is made up of raw ceramics with solvent, mixing adhesive, plasticizer, lubricant as well as aluminum oxide.

First of all, it fabricates with the raw ceramic material, secondly coat the material, and then carry out the circuit tracing on tungsten or molybdenum metals. Finally, if the circuit tracing is achieved, it can bake the boards between 1600 and 1700 degrees Celsius for up to 48 hours after lamination. All HTCC baking is done in a gaseous environment, such as in hydrogen gas.

Low temperature

Unlike HTCC, low temperature co-fired ceramic PCB is made up of combining crystal glass with an adhesive substrate on sheet metal with gold paste. And then cut and laminate the circuit board before placed in a gaseous oven at roughly 900 degrees Celsius.

What’s more, low temperature co-fired ceramic PCB profits by less warpage and evolutionary shrink tolerance. In other words, comparing to HTCC and other types of ceramic PCB, ceramic PCB has s better mechanical intensity and thermal conductivity. So as using the heat dissipation products such as LED lights, there is a advantage for the thermal benefit of LTCC.

Thick film ceramic

Thick film ceramic PCB, the thickness of its conductor layer may exceed 10 microns, but not more than 13 microns. In general, the conductor layer is printing the silver or gold palladium on the surface of ceramic PCB. That is to say, thick film ceramic PCB includes gold and dielectric pastes, which is done on a ceramic base material, and the pastes and backed at a temperature of 1000 degrees Celsius or below after working. So the thick film ceramic PCB is widely used for most PCB manufacturers because of the high cost of gold conductor paste.

The main advantage of thick film ceramic PCB over traditional PCB is that thick film ceramic can protect copper from oxidizing. So a ceramic PCB manufacturer can put interchangeable conductors, semi-conductors, conductors, electric capacitors, or resistors on the ceramic board. After achieving the process of printing and high-temperature sintering, all the components on the board can be laser-trimmed to their desired values.

There is a confusion about how many layers in a ceramic PCB, but it is decided by the types of ceramic PCB. The minimum number of layers used in ceramic PCB is two layers, however, there may be some more layers according to the product’s properties.

The advantages of ceramic PCB

Heat dissipation is the key benefit that ceramic has over more conventional materials such as FR-4 and metal clad PCB. Because the components are placed directly on the boards, and there is no isolation layer, the flow of heat through the boards is far more efficient. In addition, ceramic material can suffer from high operating temperatures (up to 350°C), what’s more, it has a quite low coefficient of thermal expansion (CTE), allowing for additional compatibility options for PCB design.

Compared with traditional PCBs whose substrate materials are epoxy glass fiber, polyimide, polystyrene and phenolic resin, ceramic PCBs feature the following properties:

? Excellent thermal conductivity

? Resist chemical erosion

? Compatible mechanical intensity

? Make it easy to implement high-density tracing

? CTA component compatibility

So it can be seen that the reasons why the ceramic PCB is so popular are as follows:

High thermal expansion

One reason why ceramic PCB is widely used in electronic industry is that because it has high thermal coefficient expansion. The ceramic base thermal conductivity arises being quite close to silicon, while under most used connection metals at the same time. Needless to say, it can play the part of great isolators for a long time. So there is optimum property for the high thermal conductivity of ceramic PCB even under elevated temperatures so that it can be used in many devices.

Stability

There is a stable dielectric property because of the use of ceramic, the balance can change into a limited radio frequency loss so that increasing the applicability of electronic device. What’s more, despite the outward toughness, ceramic has natural resistance for most chemical used because of the ceramic base PCB. Therefore, the resistance to chemical will change to resistance to daily moisture, solvents as well as consumables.

Versatility

It is no wonder that incorporation of metal core PCB can achieve a lot of applications with a high melting point. The noble metal paste can be highly unfailing conductors because of sintering technology. So there is no doubt that the use of ceramic PCB makes a effect on being high processing temperatures while there are different devices for different operating temperatures. What is interesting is the it also allows for good thermal conductivity and distribution of heat to the different position of a device.

Durability

As you know, there is a durability in the ceramic PCB fabrication process. Because of the essential properties of ceramics, specially the toughness, which can make sure that preventing your board from daily wear and tear. Because the ceramic PCB has a quite slow aging property with the consistency of based PCB, it can be changed without worry of replacement soon. What’s more, it has a high thermal resistance as it can change to a slowed decomposition process so that extends useful life length.

Adaptability

At last, one of the prominent advantages of ceramic PCB is that using the metal core in the engineering process. It can change to be the rigid carriers so that provides mechanical stiffness, making it easy to use between fluids and solids as the roughness and wear resistance are great, so it can be used in various industrial position.

Why use ceramic PCB over other boards?

Thermally conductivity

As you know, ceramic has more advantages comparing to MCPCB, such as great characteristic of high working temperature, high thermal conductivity, good insulation and thermally performance, which can make a difference of material. What’s more, ceramic PCB has a high efficient thermally conductivity.

Price comparison

Only in the products with a great property can you see the ceramic PCB, however, there is no existent in the ordinary products. So the ceramic is replacing the entire printed circuit boards to reduce the complexity of fabrication and design, as well as improving the performance.

Technology practices

Because ceramic PCB has a high thermal conductivity, stability and inertia, what’s more, it has compatible CTE with the leadness ceramic chip carrier and feature, so there is no doubt that ceramic PCB is the optimal solution for defeating thermal cycle failure. There are three catalogs of ceramic PCB practices: high temperature co-fired ceramic PCB, thick film ceramic PCB and low temperature co-fired ceramic PCB.

How to manufacture ceramic PCB?

First of all, It can use the silver or gold conductive pastes for placing trace connections in each layer in ceramic PCB fabrication process. In general, the metal elements or substrate are placed in each layer with a layer by layer screen printing process. In addition, it also can mechanically punch the vias in an unburned layer, or drill the microvias with a laser.

Secondly after printing and stacking the ceramic layers, it will bake the whole stack in an oven. In general, what the firing temperature needs for baking the ceramic PCB is below 1000 °C, which matches the sintering temperature of gold or silver pastes material. So the low temperature bake process is what allows the gold or silver in ceramic PCB.

However hot pressing/baking and sintering process for multilayer PCB makes it easy to integrate passive components immediately into the internal layers of a ceramic PCB. It is impossible in a board fabricated with FR-4 material, so the PCB designer can increase component and connection density on internal layers.

![]()

Application of ceramic PCB

Now ceramic PCB has been widely used because of its high thermal conductivity, low CTE, low dielectric constant and chemical erosion resistance.

Memory module

For example, a company from Japan had created 1Mbit SRAM memory module with making use of multi-layer ceramic PCB containing 4 IC chips, contributing to high reliability and high density assembly. What’s more, a American company had created missile, telecommunication products and aerospace products with ceramic PCB. What the common feature all of them shared is that they can be used in extreme environment. Multilayer ceramic PCB and packaging components have enough intensity and shock vibration resistance capability at warhead.

Receiving/Transmission module

There is a American company that creates receiving / transmission module for radar with ceramic PCB. Aluminum nitride has high thermal conductivity and low CTE, laying a good foundation for ceramic PCB in receiving/transmission module.

Multi-layer interconnect board

There are more components in the same PCB area for ceramic PCB to be compatible with miniaturization of electronic products, it has more probabilities for ceramic PCB in the application of multilayer interconnect board.

Analog/Digital PCB

What’s more, a company from Japan made use of LTCC PCB to fabricate analog/digital PCB so that reduces the parasitic capacitance by about nine tenths. It not only effectively gets over crosstalk interference of circuit tracing, but also reduces volume and weight of circuit.