What is heavy copper PCB?

1. The definition of heavy copper PCB

2. The benefits of heavy copper PCB

3. Heavy copper PCB Capabilities

4. Application of heavy copper PCB

5. Your heavy copper PCB in PCBGOGO

With the development of society, there is a great demand for heavy copper PCB. Now heavy copper PCBs have been widely used in various electronic industries. In general, heavy copper technology can realize complicated switches in limited space combining the circuitry for high current levels, as well as is good for heat dissipation. Multilayer and double-sided are the most common designs we know. What’s more, thick copper PCB technology makes it possible to combine great layout structures on the external layers and heavy coppers layers in the internal layers.

The definition of heavy copper PCB

Heavy copper PCB is also known as thick copper PCB, in which there are 3 ounces (oz) of copper or more on the internal and external layers of a printed circuit board. The circuit board with a copper thickness of more than 4 oz per square foot (ft2) is also categorized as a heavy copper PCB. Extreme copper means 20 oz per ft2 to 200 oz per ft2.

The reason why heavy copper PCB is the reliable wiring platform is that the thicker plating in the through-holes circuits and an appropriate substrate combined with copper weight. Heavy copper conductors can improve the whole PCB thickness considerably, so it needs to take the copper thickness into consideration as PCB design. The width and thickness of thick copper determine the current-carrying capability.

The benefits of heavy copper PCB

The main benefit of heavy copper PCB is the capability to support frequency to excessive current, elevated temperatures and recurring thermal cycling, which can do harm to aregular circuit board in seconds. What’s more, there is a great demand for heavy copper PCBs in the computer, automotive, military, and industrial controls.

In additions, the heavy copper PCB board is also used in other purposes:

In addition, there are some other benefits of heavy copper PCB as follows:

1. Compact product size because of several copper weights on the same layer of circuitry;

2. Onboard high-power-density planar transformers;

3. Heavy copper-plated vias pass the elevated current through the PCB and are good for transferring the heat to an outer heat sink.

Heavy copper PCB Capabilities

PCBGOGO is a highly experienced PCB manufacturer that can develop and produce a superior heavy copper PCB product of the highest quality. We can offer a thick copper PCB manufacturing service that uses copper weights of up to 13oz.Check our capabilities in the following table:

|

Feature |

Capability |

|

Material |

FR-4 Standard Tg 140°C, FR4-High Tg 170°C

|

|

Min. Track/Spacing |

For External layers: 4oz Cu 9mil/9mil,5oz Cu 11mil/11mil 6oz Cu 13mil/13mil,12oz Cu 20mil/32mil

For Internal layers: 4oz Cu 8mil/12mil,5oz Cu 10mil/14mil 6oz Cu 12mil/16mil,12oz Cu 20mil/32mil

|

|

Min. Hole Size |

10mil |

|

Max Outer Layer Copper Weight (Finished) |

15oz |

|

Max Inner Layer Copper Weight |

12oz |

|

Board Thickness |

0.6-6mm |

|

Surface Finishing |

HASL lead free, Immersion gold, OSP, Hard Gold, Immersion Silver, Enepig |

|

Solder Mask |

Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green |

|

Silkscreen |

White, Black |

|

Via Process |

Tenting Vias, Plugged Vias, Vias not covered |

|

Testing |

Fly Probe Testing (Free) and A.O.I. testing |

|

Build time |

5-10 days |

|

Lead time |

2-3 days |

Application of heavy copper PCB

Needless to say, now heavy copper PCB has been widely used in various electronic industries, such as heat dissipation, high power distribution, planar transformers, as well as power converters, and so on. What’s more, there is a great demand for heavy copper PCBs in the computer, automotive, military, and industrial controls.

In additions, the heavy copper PCB board is also used in other purposes:

1. Power supplies, power converters

2. Automotive industry

3. Welding equipment

4. Power distribution

5. Power Line Monitors

6. Torque Controls

7. Overload Relays

8. Protection Relays

9. Solar panel manufacturers and so on.

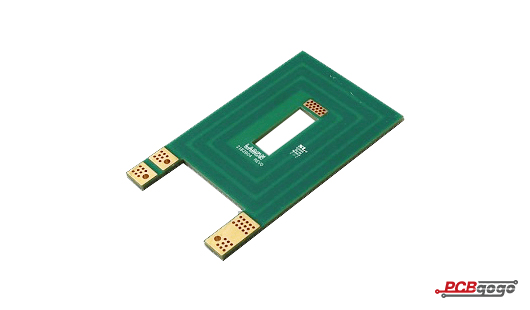

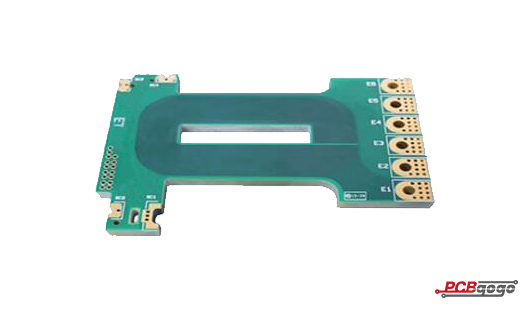

Your heavy copper PCB in PCBGOGO

In PCB fabrication, heavy copper PCB requires the special technology so that makes it difficult to operate and have some technical thresholds, so heavy copper PCB is more expensive to fabricate than other regular circuit boards. Even if the price is not cheap, quality and service will be best.

With over 10 years as an industry leader, PCBGOGO is one of the most experienced PCB and PCB assembly manufacturer in China. We are highly specialized not only in quick-turn PCB prototype and PCB assembly, but also medium and small volume PCB fabrication, the satisfaction of customers is our goal, we will try our best to fabricate your board with the highest quality to meet your demands and committed to adhering to the strictest standards in PCB fabrication and assembly.