Whether you are making a robot or any other electronic projects, it is possible that you will prototype the wiring on a breadboard, and then fabricate a permanent circuit on either perforated board or a printed circuit board. And it will control the most its functions with a board. What’s more, the electronic designers knows what type of board is most suitable for your electronic project when it comes to fabricating the board.

There are two main types of PCBs to fabricate: a printed circuit board (PCB) or breadboard. In fact, one is greatly used in custom and specific projects, however the other is fit for more general projects. None is better than the other as they have different purposes, so you can decide which you need based on your demands.

What is printed circuit board prototype?

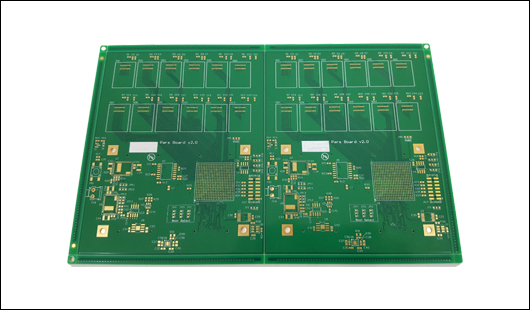

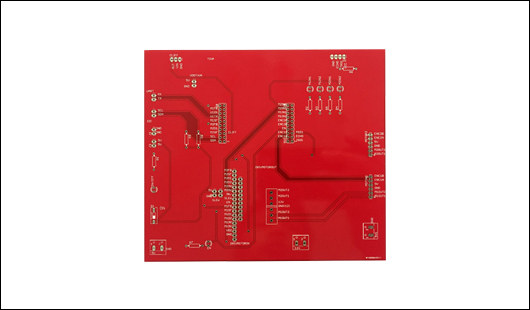

PCB prototype is an important process to your project’s development, which is a trial manufacturing for the printed circuit board before mass production, electronic engineer is designing the circuit and that is mainly in doing small volume trail manufacturing for PCB manufacturer after designing the circuit and finishing PCB layout for the electronic engineer. However, there is no limit for PCB manufacturing quantity, generally speaking, PCB prototype is the best practice method to verify the quality of a design before proceeding.

undefined

PCB is the support body of electronic components and the carrier of electrical connection of electronic components, which mainly plays the role of support and interconnection. What’s more, the PCB will be your finished product. Now printed circuit board (PCB) is widely used in various electronic and related products.

What is a breadboard?

undefined

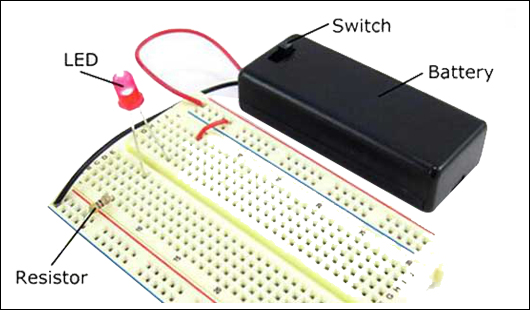

Breadboard, also known as protoboard, which is the bread-and-butter of DIY electronics. A breadboard is a simple device designed to let you create circuits without the need for soldering. It is a rectangular plastic board with a bunch of tiny holes, and the holes can make it easy to insert electronic components to prototype an electronic circuit, such as this one with a battery, switch, resistor, and an LED (light-emitting diode). however, breadboard will have a less permanent compared to a printed circuit board, so you can remove and change the breadboards if needed as they have sockets that you push the components into. It can’t be denied that a breadboard will be more for experimenting ,designing and testing circuit connections before making it permanent.

Where does the name "breadboard" come from?

You might be wondering what any of this has to do with bread. The term breadboard comes from the early days of electronics, when people would literally drive nails or screws into wooden boards on which they cut bread in order to connect their circuits. Luckily, since you probably do not want to ruin all your cutting boards for the sake of an electronics project, today there are better options.

How does a breadboard work?

You need to make a breadboard before creating the permanent circuit board because it can remove and change components on a breadboard. What’s more, you will draw out the schematics and connect the wires accordingly.

As you know, the centre of PCB is the prototyping region, which is made up of two rows of five holes. There is a channel between the two rows, you can place a chip with pins on either side so that prevent them from connecting together. Also, you can seek out power busses (either one or two) on the side of the breadboard for working power and grounding.

In fact, designing breadboards are used for integrated circuit (ICs). you can place an IC chip over the channel, which you can access to the pins on either side of the existing chip. What’s more, connecting a resistor to the power bus into the channel, at the same time taking an LED from the ground bus to create the whole circuit.

undefined

Breadboard and Printed circuit board

On one hand, a breadboard is usually used as the first step before creating a printed circuit board. You can change and move circuits that are otherwise permanent on a PCB with a breadboard. On the other hand, breadboards are used for design and investigation, while the boards are for your finished products.

The advantages of breadboard:

-

You can rapidly change connections and test various plans in a development phase.

-

It’s easy and fast to assemble as there are no permanent solder connections.

-

You can also change various components such as the capacitor or resistor value.

-

You can add an ammeter anywhere with shifting wires (breaking into) any branch of your circuit. What’s more, the current measurement on PCBs require you to break tracks or add extra resistors in your design.

undefined

The advantages of a printed circuit board:

-

The board is permanent to have an electronic device worked.

-

PCB has a better current carrying capacity comparing to a breadboard, you can make your traces wider to take more current so that work well.

-

You can add terminals to your printed circuit board for external connections.

-

You can mount heat-sinks to the board so that have them rigid.

-

There is widely used in electronic devices.

-

A PCB has a cleaner look than a breadboard (when manufactured correctly).

-

It is normally easier to understand the circuit on the board. None of those looping wires going everywhere.

-

Nobody is going to buy your great, fantastic, electronic design (product) on a breadboard.

Should you use a PCB or a breadboard?

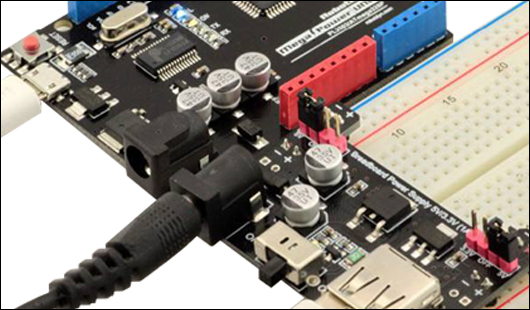

There is a time when you would use a breadboard over a PCB, and the other way around. According to what you are making and the stage you are at, which will help you decide when to use either a breadboard or a PCB.

When to use a breadboard?

In normal, the breadboard can be used in testing with connections and circuits. So you can move circuits around without damaging the printed circuit boards because the board is not permanent. But, there is a minimal current capacity and you’d better prepare for work before developing the actual board as it is not a permanent board.

undefined

When to use a PCB?

As you know, the printed circuit board can be used for the actual electronic device. What’s more, you can develop that into a printed circuit board after testing out the breadboard and finding the perfect design for your project. Needless to say, PCB is a permanent device in electronics as it needs to solder, so the board has been widely used in your electronic projects.

PCBGOGO highly specialized not only in quick-turn PCB prototype and PCB assembly, but also small and medium volume PCB fabrication. We have three factories, established over 17,000 M2, which are fully compliant with the standard of ISO 9001:2015 Quality Management System. All the PCB boards and assembled PCBs are high quality and certificated with UL, REACH, RoHS and CE. Till now, we can finish 3000+ PCB board and assembly orders per day and our accumulated customers have reached up to 100,000.