Choosing the Best PCB for your Design

While designing your Printed Circuit Board layout, the most important thing is to choose the correct PCB in relevance to your design. There are a number of PCB types to choose from and each has its own advantage. However, only a few might fit the application you desire.

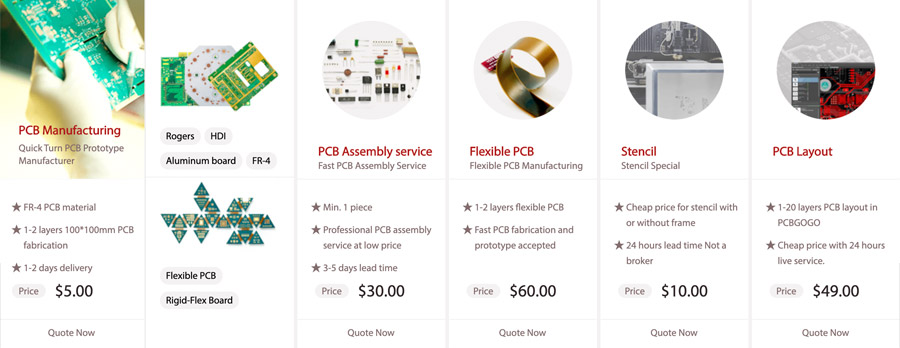

While choosing your PCB, there are a few important things to keep in mind. The application you need to choose the PCB for, the size of PCB suitable to your requirements, and the price range you want your PCB to lie in.

undefined

1: Application:

The application your PCB needs to work with should be taken into account while designing. There are limitations that not all designs can cross and so it is necessary to design your PCB accordingly.

undefined

RF Design: RF (Radio Frequency) design is used for high frequency PCBs; they would be used in wireless applications, smart phones, security etc. There are a number of factors to consider such as cross coupling, radiation etc. The PCB materials that would fit this application would include Rogers or IS410.

High Power:High Power usually means that the application may require a lot of power to operate; this would include larger machinery and electronics. The greatest factor would be heat dissipation during processing. Usually the copper thickness is increased for such PCBs.

undefined

2: Size and Fit:

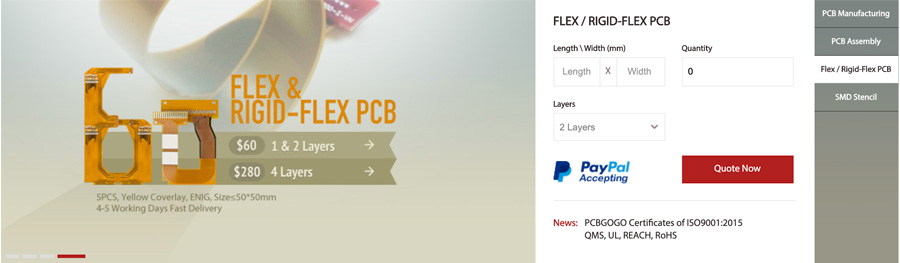

The usual trend is the more common the use, the lesser the price and vice versa. The size of PCBs can range from extremely small to extremely large. The thickness could also vary. Usually if the PCB is too large, the number of layers can be increased and connections are made between the layers, this helps to reduce the size. Two major types of circuits would be flexible and rigid-flex circuits.

Flexible circuits are available in one to more than one layer. They are widely used ever since their development in the 1950s. Usually the applications they are used in require space and flexibility. The major advantages of flex circuits include lesser weight, more heat dissipation and faster manufacturing. The downside would be the increased cost during prototype production, the repair of such circuits is very difficult and such circuitsare more prone to damage.

Rigid-Flex Circuits are a combination of flexible and rigid boards. The nomenclature of such boards is typically 2F6R (2 Flexible and 6 Rigid). They were originally designed for military use. The major advantages include being less expensive in large volume production, using lesser space, decreased weight and more reliability etc. The disadvantage to using flex-rigid circuits would be that the designing of such PCBs is harder and many PCB design packages do not support the design (a 3D design package is required), the pricing for prototypes is high, the polyimide shrinks after copper etching, the assembly is to be strictly monitored as it may produce fractures.

3: Price:

Rigid PCBs as stated before are the most commonly used PCBs. The pricing of PCBs increases with the increase in layers. And with the increasing complexity of applications, the requirement of layers is also constantly increasing.

The most common material for PCB manufacturing is FR4 material, which is a fiber glass epoxy laminate. FR is the acronym for Flame Retardant) and such material based PCBs can withstand 120 degrees to 130 degrees. Other materials such as TG170, TG150 and CEM (Composite Epoxy Material) can be used to improve thermo-mechanical properties. They are usually used in application which require more power and hence more heat dissipation.