How Is Solder Mask Applied On PCB?

Solder mask is a protective coating for the bare board, bare boards is not only to prevent accidental solder bridging as assembly covered with mask, but also protect the board from the environment.

What is solder mask?

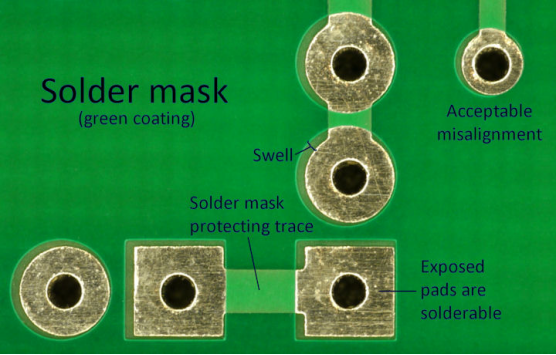

Solder mask is a thin lacquer-like layer of polymer that is usually applied to the copper traces of a PCB for protection against oxidation, and prevent solder bridges from forming between solder pads. A solder bridge is an unintended electrical connection between two conductors with a small blob of solder, and the boards can prevent this from happening with solder masks. Solder mask is not always used for hand soldered assemblies, however it is important for mass production boards that are soldered automatically using reflow or solder bath techniques. Opening needs to be made in the solder mask wherever components are soldered after applied, which is accomplished using photolithography.

How is solder mask applied to your PCB?

Solder mask is made up of a polymer-layer that coating over the metal traces on a board. There are a number of different types of mask material, the best option for your PCB according to your application and cost. Printing a liquid epoxy over the board with a silkscreen is the most fundamental solder mask option, which is like airbrushing face paint on with a stencil.

Solder mask comes in different media depending upon the demands of the application. The lowest-cost solder mask is epoxy liquid that is silkscreened through the pattern onto the PCB. Other types are the liquid photoimageable solder mask (LPSM) inks and dry film photoimageable solder mask (DFSM). LPSM can be silkscreened or sprayed on the PCB, exposed to the pattern and developed to provide openings in the pattern for parts to be soldered to the copper pads. DFSM is vacuum laminated on the PCB then exposed and developed. All three processes go through a thermal cure of some type after the pattern is defined.

In electronic design automation, the solder mask is treated as a layer of the printed circuit board, and is described as a Gerber file like any other layer, such as the copper and silkscreen layers.

What solder mask should you use?

An appropriate solder mask depends upon the physical dimensions of the board, components, holes, and conductors, the surface layout, as well as the final application for your product.

First of all, please check the industry standards around solder mask and expected application if you have a PCB solder mask that will be used for medical, aerospace, telecom, or other “high reliability”industries. There are some specific requirements that replace whatever else you learn on the internet.

You will need a photoimageable solder resist for most modern PCB designs. The surface topography will depend on whether to use a liquid or dry application. And a dry application is that lay down a uniform thickness across the entire surface. But it will be the best for dry mask adheres of your PCB surface is very flat. And if there are complex surface features, you’d better select with a liquid (LPISM) so that there will be a better contact with the copper of your traces and the laminate.

What’s more, you can also get the different finishes on the mask layer. Contact with your PCB manufacturer about what they have, as well as how it will make an effect on production.

How do you include the solder mask in your design?

The solder mask should be its own layer in the Gerber files as you design your PCB, and check the design rules for a solder mask layer. In general, you should use a two mil border around your feature if the solder mask is not positioning on the center perfectly. In general, the minimum distance between pads is 8 mils so that the mask is enough to protect the solder bridges from forming. So it’s important for you to choose PCB design software if you are creating the more difficult PCB designs. It will adjust the design rules based on your needs.

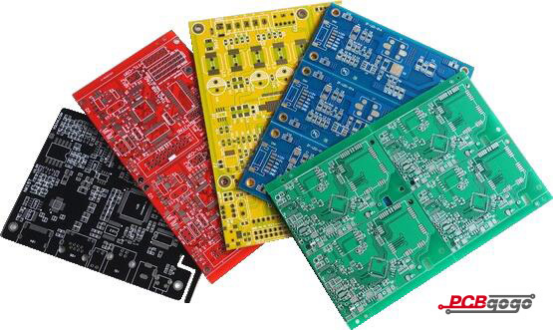

What kinds of solder masks do we have in PCBGOGO?

As you know, solder mask is very important when it comes to fabricate your PCB, green is the most common color for solder mask, but there are many other colors available. Some colors PCBGOGO also uses:

Green

Red

Blue

Yellow

White

Black

Matte Green

Matte Black

Purple

PCBGOGO will try our best to fabricate your PCBs with solder mask with the highest quality to meet your demands and committed to adhering to the strictest standards in PCB fabrication and assembly.

If you have any questions, please feel free to contact us with service@pcbgogo.com, we will be happy to help you.