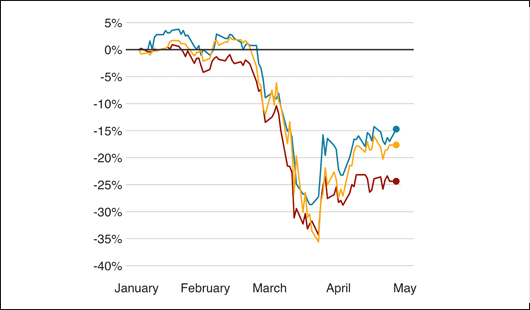

According to the current statistics from news reports, COVID-19 has spread to more than 200 countries and regions, making it a global pandemic. With the implementation of national epidemic prevention measures, the reality is generally more disruptive on all aspects of our life. This epidemic may result in long-term consequences for global business. PCB manufacturers are no exceptions.

As more and more countries and cities enter a closed state, the potential economic impact of COVID-19 has become apparent. There is no doubt that COVID-19 has a massive effect on tourism, aviation, catering, hotel, medical machinery, military, and other industries.

Now the number of infections is rising continuously outside China, but there is no specific treatment for the disease. The impact on the medical electronic industry is mainly reflected in the increased demands for clinical respiratory support equipment, such as ventilators, fog generator, oxygen generator, patient monitor, etc. At the same time, more and more medical diagnosis and treatment methods have been computerized nowadays, making the demand for PCBs in medical electronics is growing. Especially the outbreak of COVID-19 has put more urgent requests on medical PCBs.

The most urgent medical equipment in the treatment of COVID-19

The sudden outbreak of COVID-19 brought huge challenges for hospitals and society. Some necessary medical equipment is in short supply, such as respirators, extracorporeal membrane oxygenation machine (ECMO), mobile labs, mobile CT, and other sophisticated equipment. These devices play important roles in the clinical treatment of COVID-19. Besides, the demand for these devices like temperature monitors, handheld thermometers, and infrared thermometers has also significantly increased.

Quality, safety, and durability are the fundamental factors for medical PCBs. PCBGOGO is specialized in providing complete integrated solutions that can meet the particular needs in medical applications. For the urgent demands of medical equipment applied in the treatment of COVID-19, PCBGOGO is competent enough to respond to the market demand.

PCBs types PCBGOGO can provide for the medical industry

We all know that medicine always goes together with technology. The development of technology brings infinite possibilities for medical treatment. The combination of biological techniques and PCBs is beneficial in curing some problematic diseases. Various types of medical PCBs can be easily found everywhere, for example, pacemakers, defibrillators, MRI, ultrasonic equipment, CT scans, temperature monitors, and neural stimulators for spine pain treatments, etc.

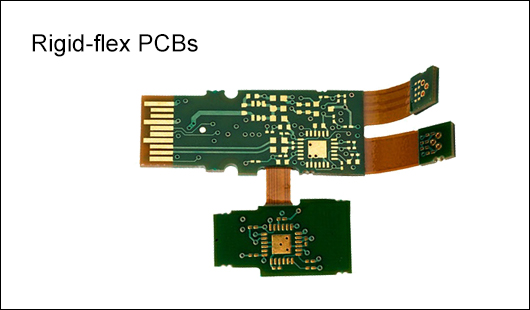

Flexible PCBs/Rigid-flex PCBs

Flexible/ Rigid-flex PCBs are used widely in implants and prosthetics; these special devices are put into patients’ bodies to replace an organ or “added” to help measure vital data or regulate certain biological functions.

But the requirements of PCBs used in these electronic devices are higher than other PCBs. First, the size and shape need to be flexible and bendable to fit specific space and entire size due to the particularity of the human body. Secondly, the materials used in PCB manufacturing must be non-toxic, corrosion-resistant, and harmless to the health. Flexible / Rigid-flex PCBs can meet above demands while remaining high resistance to damage, making them more suitable for medical devices.

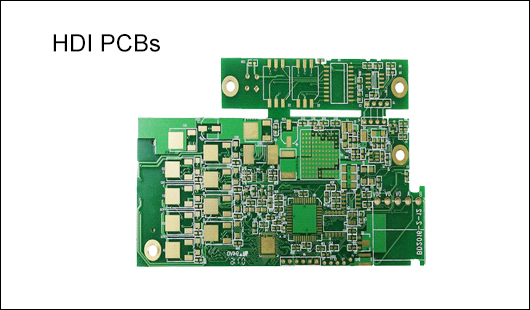

HDI PCBs

The internal PCBs and components in many medical devices must be small enough to meet the demands for special medical purposes. HDI PCBs are preferred in medical industries because they allow high-density connections to be packed in a minute space. For the implants and other complicated devices, only HDI PCBs can provide high transmission rates with small packages. HDI PCBs are the best solutions for the miniaturization trend of electronics not only in the medical industries but also in other industries like communications, automobiles, aircraft, and so on.

Medical PCB services in PCBGOGO

At present, the domestic epidemic situation in China has been basically controlled, and all the staff in PCBGOGO has returned to work after necessary isolation and observation processes. The work of factories and departments has run their ordinary course. All walks of life in China have returned to work in an orderly manner, including the PCB industry chain.

The quick turn service in PCBGOGO has also been restored. The build time of our PCB prototype is 2-3 days, and 24 hours of expedited service is also available. The lead time of PCB assembly is 7-10 days, and the component sourcing time is 7-20 days. Turnkey service for PCB assembly usually needs 15-40 days or so.

PCBGOGO does the best to resume as soon as possible while ensuring the safety and quality of production. All the staff is strictly following the epidemic prevention measures, such as wearing face masks during the whole working time, taking temperature twice a day, disinfecting the workplace regularly as required, etc. and we ensure that all the products are disinfected before shipment.

Besides, PCBGOGO prepares some discounts for medical PCB orders to help consumers from the medical industry. Please check the latest news on our website or consult online service for detailed information. At this special time, we need to cooperate to get through the hard times.