Single-Sided vs. Double-Sided vs. Multilayer PCBs

When it comes to PCBs, there are some terms you will be similar, such as single-sided PCB, double-sided PCB, as well as multilayer PCB, which can determine the complexity of a board’s structure in electronic PCB industry. However, each type of PCB has various price points and uses. Now they have been widely used in electronics and applications, such as computers, mobile phones, machinery as well as radio equipment and so on. PCBGOGO will make a basic understanding of PCB production, it can discover the capabilities of these boards compositions.

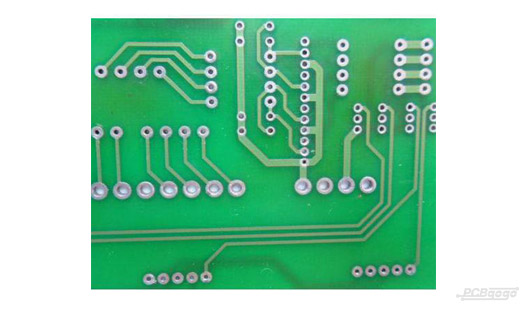

Single-Sided PCBs

Single-sided PCB, also known as single layer PCB, which is a type of PCB which comes with only one layer of conducting material on one side of the board and other side is used for incorporating different electronic components on the board. Single layer PCB is widely used in the printed circuit board design in a variety of different electronic sectors where low costs are required. What’s more, single layer PCB has been made of various of material, such as paper reinforced phenolic resin with copper foil and glass fiber reinforced epoxy resin with copper foil and so on. Needless to say, single-sided PCB is one of the most commonly fabricated boards as they are very simple and basic to make.

Single-sided boards may not have the same complexity as their counterparts, but they power a wide range of daily electronics. Since they cost so little to make, you can find them in mass production devices like:

Camera systems

Audio equipment

Power supplies

Calculators

Solid state drives

Printers

Surveillance

Double-Sided PCBs

Double-sided PCBs are the same as single-sided PCBs, but the difference is they have two sided traces with a top and bottom layer. Double-sided PCBs can mount conductive copper and components on both sides of the printed circuit board so that the traces can cross over each other. So it leads to a higher density of boards without the need of point-to-point soldering. So it’s difficult to fabricate the double-sided PCBs because they are more complex than single-sided PCBs. However, it’s better to use the double-sided PCBs compared to single-sided PCBs.

Double-sided PCBs are one of the most popular types of PCBs because they make manufacturers to fabricate more complex circuits, which can benefit uses in higher technology applications and electronics. There is an abundance of applications and electronics which double sided PCBs can be used in electronics such as:

LED lighting systems

Vending machines

Amplifiers

Car dashboards

Industrial controls

Phone systems

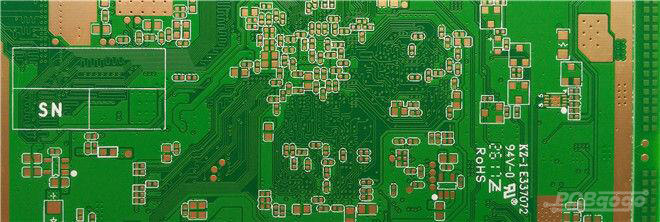

Multilayer PCBs

Multilayer PCBs can support a high level of circuit complexity as they are made up of three or more copper layers laminated together. And the manufacturers begins to use a core that has the same materials as a typical single-sided or double-sided PCB. After etching the inner core, they add a layer of prepreg, a soft fiberglass, which remains the layers together and be the hard fiberglass after the board goes through a hot press. So multilayer PCBs are durable and tough after the curing process. Needless to say, it will use one core, prepreg and copper foil for the top and bottom layers if the manufacturer is fabricating a 4 layer PCB.

There are complex technology like computers and data servers because of the high capacity of multilayer PCBs. They can be used in electronic devices such as:

Fiber optics

Smartphones

GPS systems

Scientific and space equipment

Heart monitors

Atomic accelerators

Conclusion

When you are in the process of fabricating your printed circuit boards it is important to understand the differences between types of PCBs so you choose the one that will be best for your application. PCBGOGO is here to help you get PCBs you need and offers tips to get you started in the right direction. Single sided boards are made from rigid laminate with copper on one side of varying thickness. Double-sided boards differ in that they have copper on both sides of the laminate. A multi-layer PCB has copper foil on the top and bottom and inner layer cores. Each type of PCB has its own unique advantages so work with PCBGOGO to get the one that is best for you.

If you have any questions, please feel free to contact us with service@pcbgogo.com, we will be happy to help you.