Electronic Project Engineer's Best Partner!

Only very small volume PCBA projects will be handled manually and undergo visual inspection, while majority of the larger projects are processed through reliable automated machinery. All soldering during the PCB assembly process is up to Class 1 standard, while Class 2 and Class 3 standard are also available for you to choose from.

PCBGOGO will use automated machinery to solder components on your PCB as fast as possible, making use of your pick & place CAD data. Component positions, orientation and solder quality will normally be verified using Automatic Optical Inspection. AOI technology has proven to be extremely reliable whilst looking for errors in PCBs.

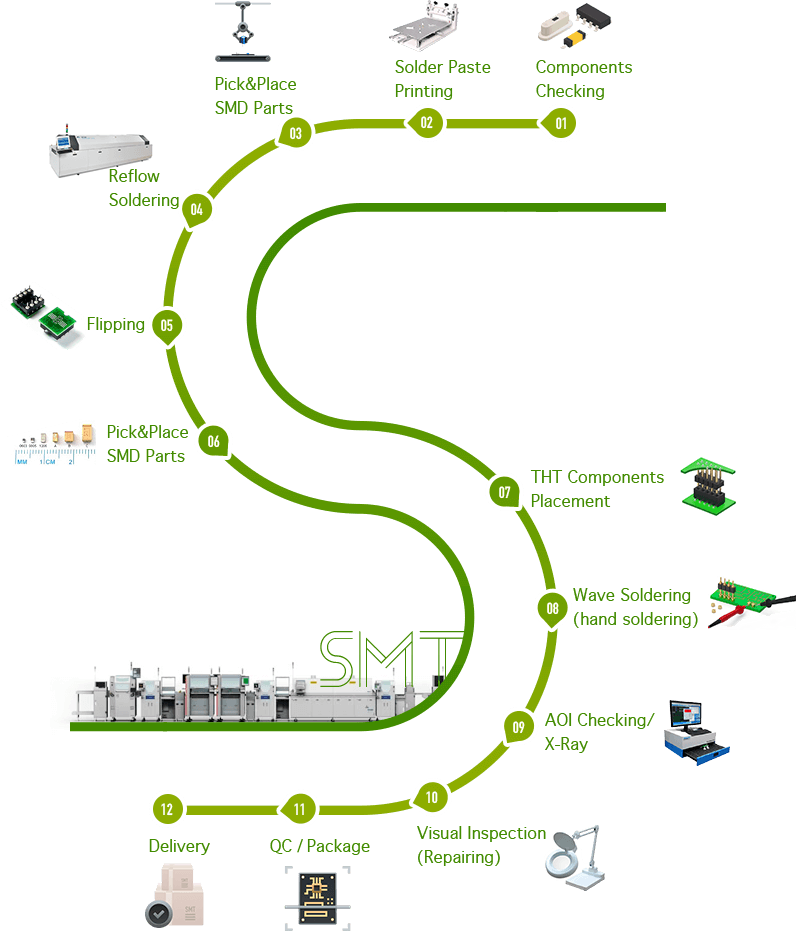

The PCB Assembly process is below:

After assembly, the PCBA photos will be provided to you so you may confirm the components position via email. Please respond to the service email on time so your order may be processed and shipped out immediately. Quote now.